Selection guide

Representative products of our company are posted in this Product Line. From each series you can choose the best and economical product for your piping system.

We also produce automatic valves with special specifications not listed in this Product Line, so please contact us separately.

Specifications and notes on products listed in this Product Line are representative contents. For detailed content please request materials for each product.

Catalog composition

Specification

Adaptive fluid is indicated by symbol mark for each valve. Please use it as a guide for selection. Please note that it may not be used depending on the properties and state of the fluid.

Water

Water Oils

Oils Gas

Gas Steam

Steam Chemicals

Chemicals Sea water

Sea water Slurry

Slurry

Product code

All products have a product code with alphabets and numbers.Please contact us with this product code for inquiries and orders.

Production range

Products include standard products and semi-standard products.

Standard:Standard delivery time.

Semi-standard:Delivery confirmation is required.

Depending on various circumstances, standard products may not be available at standard delivery date. Please be sure to check the delivery date.

Rank for sizing of actuators

The operating torque of the valve is greatly affected by fluid properties, differential pressure, temperature and sheat material. In consideration of various conditions, selection of actuators is necessary.

| Code of rank |

1 | Light load | Lubricant fluid. It can be selected with fluid properties in limited pressure and temperature range. |

|---|---|---|---|

| 0 | Standard | Clean fluid (100 cP or less) or for standard fluids of that series. | |

| 2 | Heavy load | Non-lubricating fluid, solvents, viscous fluid(100 ~ 500cP) |

It is necessary to make a consultation in case of using it for fluid containing foreign matter, powder, highly viscous fluid (500 cP or more), sticky fluid. Consultation is necessary when there is a risk that components of fluid will precipitate and adhere inside the valve.

Material

The ball material of the ball valve may differ in manufacturing method depending on the nominal diameter etc. Although the material symbol changes depending on the part manufacturing method, it is indicated by a representative symbol on this website.

Cv value, Inherent flow characteristic

Cv value is the coefficient of fluid flowing ability. Each valve has a

unique Cv value for each nominal diameter. Cv value is defined as follows.

Numerical value expressed in US gallons / minute when flowing pure water at 15.6 degrees keeping the differential pressure across the valve at 1 psi.

Cv value represents the ability to flow a fluid.

Since it is possible to calculate the required Cv value from the required flow rate and the expected differential pressure (Pressure

loss), it can be used for selecting the model and nominal diameter.

For calculation of Cv value, refer to technical data on the catalog. A graph of intrinsic flow rate characteristics is shown on the page of the valve suitable for proportional control, This graph shows the change in Cv value relative to the travel of the valve.

When the differential pressure across the valve varies with the opening of the valve, it is not proportional to the actual flow rate.For selecting the proportional control model, refer to the selection method of proportional control valve. In the case of a full port two-way valve, Cv value is not defined

because the fluid passage of the valve is almost the same as the inside diameter of the inlet and outlet pipes.

Operating pressure and temperature range

The operating temperature range of the valve is affected by fluid pressure. Refer to the graph of operating pressure and temperature range for selection of valve. Due to fluid properties, it may not be usable even within the operating pressure and temperature range. Please inform us of fluid properties / specifications when selecting. When selecting a valve, it is necessary to inform us about the properties of the fluid. When using it for fluid which becomes gas-liquid mixture state such as water of temperature exceeding 100 degrees, please use steam compatible type valve.

Product life of automatic valve

Actuators has durability of 200,000 times or more. Valve life span varies greatly depending on fluid properties and usage. If you use a ball valve for proportional control, the seat leaks in a short period of time. Because the ball is in the middle position for a long time, the sealing surface of the ball-seat is deformed or uneven wear is caused. If seat leakage is a problem, please use ON-OFF type valve together. The butterfly valve can be used in the middle position without problems. When installed in an environment exposed to direct sunlight and rain breeze, automatic valves life will shrink extremely. It can be used for a long time and safely by providing a sunshade and rain cover.

Notes on valve selection

Abnormal pressure

Because of the structure of ball valve, abnormal pressure rise at pocket occurs if the fluid is liquid and the temperature fluctuates. It is necessary to select an abnormal pressure rise prevention model in case the abnormal pressure rise happens by temperature rise at the pocket during valve full closing or full opening. (Some models can be supported by options.) In the case of plastic valves, certain liquids such as H2O2 and NaClO are prone to vaporization (outgassing), causing irregular pressure rises and potentially damaging the valve.

Flow velocity

The flow velocity when the valve is full opening should be 3 m/s in case of liquid and 30 m/s or less in the case of gas. If this flow velocity is exceeded, please contact us.

Cavitation

When the liquid passes through the narrowed part inside the valve, the flow velocity may increase, and the liquid whose pressure has decreased may vaporize. After the air bubbles pass through the throttled part, the flow velocity and pressure return and are crushed. This phenomenon occurs suddenly in a very short time, so it accompanies a strong shock wave, vibration and noise. Cavitation is the phenomenon that this bubble is generated and crushed. Cavitation damages (erosion) valves and piping interior. Calculate the average flow velocity inside the pipe and select the nominal diameter so that it is below the maximum flow velocity inside the pipe.

Water hammer

Pneumatic actuated valves have a high operating speed, a water hammer phenomenon sometimes occurs. If there is a possibility that a water hammer may occur due to fluid and piping conditions, adjust the operating speed of the actuator using the speed controller. For valves with a nominal diameter of 40 A or less we recommend more than 1 second and for 50 A or more we recommend more than 2 seconds.

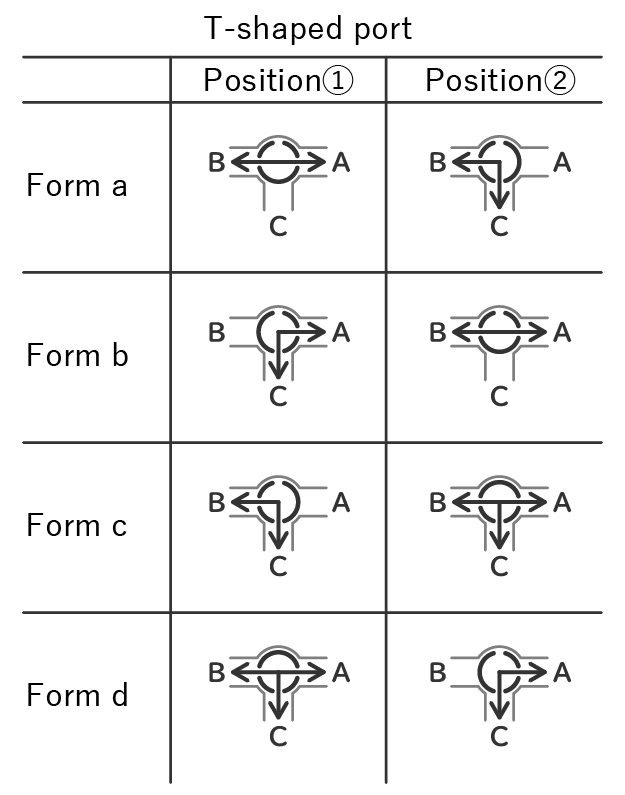

Leakage 3-way ball valve

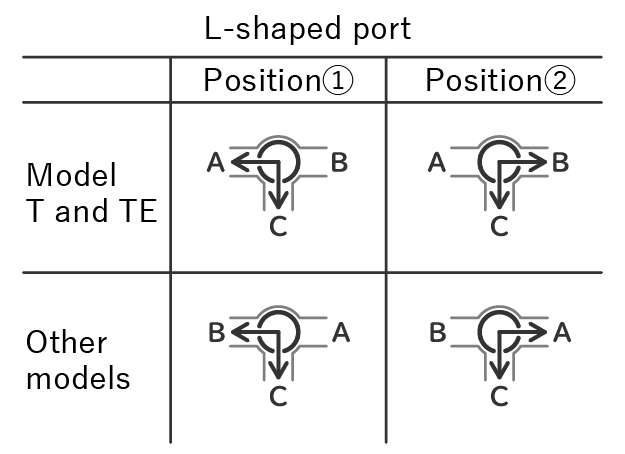

The ball of the 3-way valve has L port and T port type, and it is a flow paths of the picture below. When choosing T port type, please write flow paths code in product model code.

It should be noted that, if the line pressure of the closed bore is higher than that of the open bores, a small rate of fluid leakage may occur from the closed bore. Three-way valves with a trunnion structure (L3, T3 series) sealing performance even when the pressure of the closing side port is high.

How to select a proportional control valve

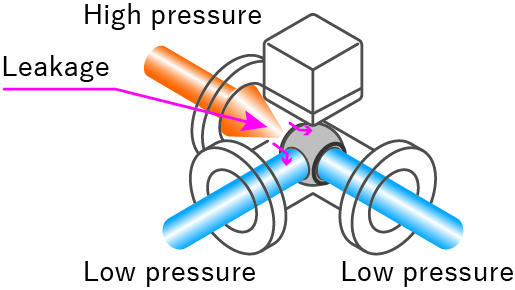

Proportional control valve

In order to bring the controlled object's temperature, flow rate, concentration etc., to the desired state, use the proportional control valve with the image as below. The controller receives the signal from the sensor and changes the opening degree of the proportional control valve so that it becomes the target value.

The valve travel is proportional to the output signal value of the controller. Valve travel and flow rate are not proportional. The flow rate is determined by the Cv value in the valve travel and the differential pressure across the valve at that time. The valve has its own Cv value, flow rate characteristic, range ability, each affecting control.

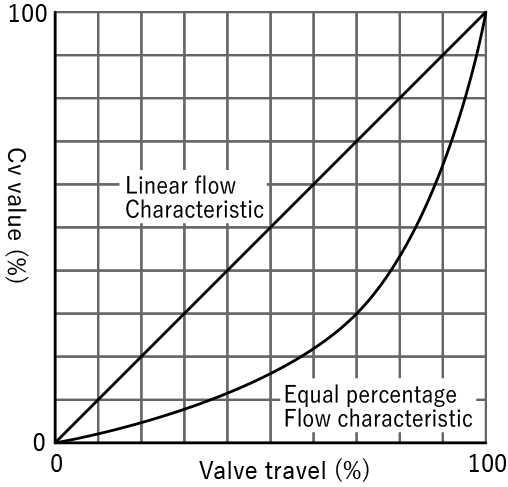

Inherent flow characteristic

The vertical axis of the inherent flow rate characteristics table shows the percentage of Cv value rather than flow rate.

The valve travel and flow rate are proportional only when the differential pressure across the valve is always constant regardless of the valve travel. Valve of linear characteristic is suitable for this case.

For general use conditions, as the valve travel increases, the differential pressure decreases, so using a valve with an equal percent characteristic will make the actual flow rate and the valve travel close to each other, resulting in better controllability.

Range ability

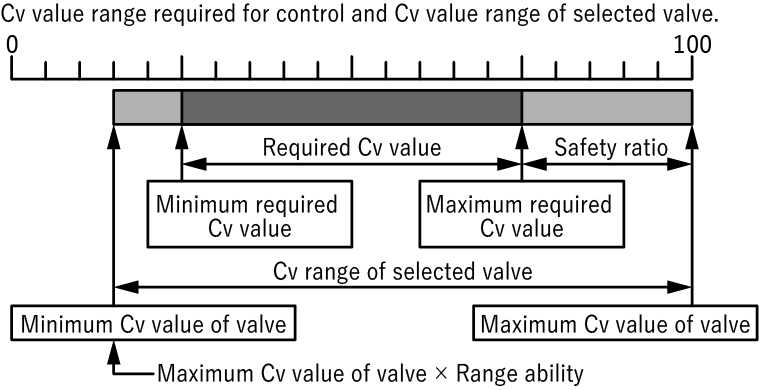

Range ability is set for each model in the proportional control valve. Range ability is the range that can be controlled. It can be thought of as the ratio between the maximum controllable Cv value and the minimum Cv value. In the case of a valve whose full-open Cv value is 75 and range ability is 100 : 1, the minimum valve travel that can be controlled is the valve travel at which the Cv value is 0.75.

Calculation of required maximum and minimum Cv values

Calculate the Cv value when flowing the required maximum flow at the expected minimum differential pressure across the valve. Please select a valve with a fully open Cv value that allows for a certain safety factor for the calculated value. Calculate the Cv value when flowing the required minimum flow at the maximum expected valve differential pressure. This value can be used above the "Full open Cv value of valve × Range abilities".

Notes on nominal size selection

Even if the nominal size of the control valve is too small or too large, control will be adversely affected. If the nominal size is too small, it becomes impossible to secure the necessary flow rate. If the nominal size is larger than necessary, phenomena such as hunting are caused, the operation becomes unstable, product life may be extremely shortened. In order to prevent these, it is necessary to select the proper nominal size considering the entire process. A certain safety factor (25 to 60%) must be provided to ensure a stable maximum flow rate. If the safety factor is too high, the stability of control will deteriorate and the range ability will be small. It is important to consider a moderate safety factor taking into consideration the pressure loss of the controlled object, variation of the set point, etc. Even for valves with high range ability, it should be within 4 times the required maximum Cv value.

Notes on piping conditions

The mounting position of the control valve greatly affects the controllability. Vibration, noise, hunting may occur due to turbulent flow generated by the elbow or reducer. To prevent these phenomena, please keep straight pipe section of more than six times the pipe inner diameter upstream and downstream of the valve. Increasing the flow rate with the reducer improves the controllability because the differential pressure across the valve can be secured. When using the reducer, please pay attention to the required maximum Cv value. To reduce the occurrence of drift and turbulent flow, please use a smooth shape reducer.

CONTACTIf you have any questions or concerns,

please contact us first.

Selection request, document request, other inquiries